ONSHORE FIELD JOINT COATING

Company Services Swiss SA Group provides Field Joint Coating services & materials consistent with companies’ requirements and satisfying contractors’ needs.

CSS SA Group matches Technical Specifications while optimising installation rate.

CSS SA Group act as a real partner, not a mere supplier, and it’s there to make it happen.

ONSHORE ACTIVITIES

SURFACE PREP

SURFACE PREPARATION

CSS SA Group designs, tests, and develops equipment for surface preparation (Power Tool / Grit Blasting) customised to be consistent with companies’ requirements & satisfying contractors’ needs. Full range of closed, open, manual, semiautomatic, and fully automatic surface preparation equipment are available, and improvements are continuously developed further to optimize results and minimize cycle time.

CSS SA supply surface preparation equipment in a complete spread to fully manage the surface preparation activities (i.e., compressors, accumulating tanks, dryers, vacuum blasting recovery systems, on pipe rotating frames fully automatic, semiautomatic, and manual, consumables, quality control tools, etc.). CSS SA Group has achieved the shortest cycle times even on large diameter pipes, to satisfy the installation rates required.

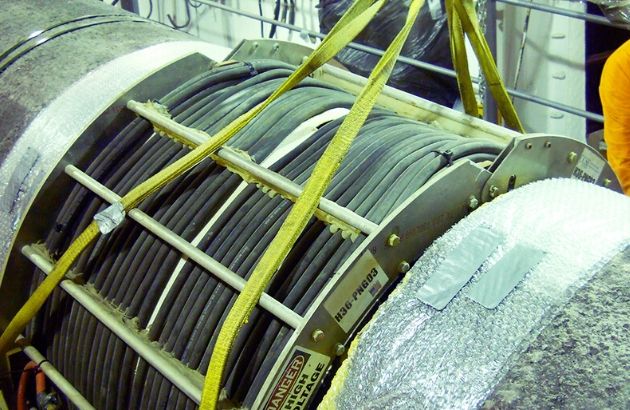

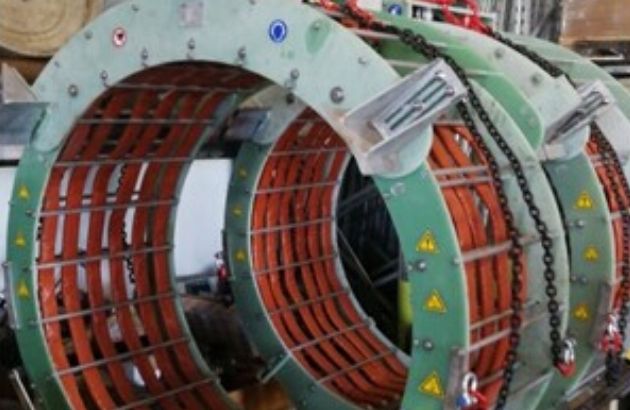

INDUCTION HEATING

INDUCTION HEATING ONSHORE

CSS SA Group works with leading Induction Heating equipment manufacturers to offer to Clients the tailored induction heating onshore equipment requested to cope with project-specific dimensioning and desired heating cycle time.

Both diesel and electrical induction heating equipment are available. Typically, CSS SA provides 120 kVA to 350 kVA induction heating onshore generators with tailored induction heating coils to match precisely the field joints dimensions.

2-3 LAYERS HSS

APPLICATION OF 2-3 LAYERS HSS

CSS SA Group works with leading HSS manufacturers and Company Services Swiss SA Group Installation Technicians to gain their approval for the Projects’ installation of the required HSS material. CSS SA Technicians have installed tens of thousands of 2-layers PE HSS, 3-layers primer activated PE HSS, 2-layers PP HSS, 3-layers primer activated PP HSS of major manufacturers.

INFILL WITH Pus

INFILL OF CWC COATED LINES WITH PUs

CSS SA Group manufactures and applies a complete and comprehensive range of HDPUF matching any specification requirement and with the shortest possible cycle time. CSS SA Group HDPUFs offer short cycle time maximizing the installation rate; as an example, Company Services Swiss SA has proved cycle time of fewer than 3 minutes on a 42” with a very thick 5” CWC.

CSS SA Group HDPUFs offer short cycle time maximizing the laying rate; as an example, Company Services Swiss SA have proved cycle time of fewer than 3 minutes on a 42” with a very thick 5” CWC. CSS SA HDPUFs range of materials is available from dry densities of 100 kg/m3 to even over 200 kg/m3, to achieve the required mechanical strengths. As a manufacturer of HDPUFs, CSS SA tailor the material to the specific project requirements (e.g., joint volumes, ambient conditions, desired reactivity, hardening time, etc.) to optimize the final result for both companies and contractors fully.

CSS SA Group manufactures and applies a complete and comprehensive range of Solid PUs matching any specification requirement and with the shortest possible cycle time. CSS SA Group SOLID PUs offer short cycle time maximizing the installation rate and types are available – depending on the requirements on the materials – for high and low-pressure PU injection equipment or even for manual mix & pour for special applications (spools, tees, risers, pipelines crossings, etc.).

CSS SA SOLID PUs range of materials is available from moulded densities of 900 kg/m3 to even over 2200 kg/m3, to achieve the required mechanical strengths. As a manufacturer of SOLID PUs, CSS SA tailor the material to the specific project requirements (e.g., joint volumes, ambient conditions, desired reactivity, hardening time, etc.) to optimize the final result for both companies and contractors fully.

MULTI COMPONENT

APPLICATION OF MULTI COMPONENT LIQUID COATING

CSS SA Group is working together with leading liquid coating manufacturers of Liquid Epoxies and Liquid Polyurethanes, and CSS SA Group Onshore Technicians gain their approval for installation of the requested liquid coating material.

CSS SA equipment is tailored on the onshore pipeline installations requirements to optimize the application matching the liquid coating manufacturer’s instructions and satisfying the contractors’ requirements.

THERMAL INSULATION

THERMAL INSULATION MATERIALS

CSS SA Group manufactures and applies Solid PUs specifically designed to match low lambda values offering excellent thermal insulation even at the field joint up to +120°C. As an example, Terthane S/TI SOLID PU for Thermal Insulation, offer outstanding mechanical properties with a k value a slow as 0.19.

Company Services Swiss SA Group’s Technical and Commercial responsiveness is happy to receive your enquiry and reply in the shortest lead time.