SUPPLY OF SPECIAL MATERIALS

Company Services Swiss SA Group, in addition to the specially designed Polyurethanes for Field Joint Infill, have developed several unique materials to cover special applications of the O&G pipelines.

These unique materials have been further developed, enhanced, and proven throughout the many years of experience.

SPECIAL MATERIAL FOR ANODES GAP INFILL

ANODE GAP INFILL BEFORE APPLICATION

The gap between the anode and the CWC needs to be infilled, including between the anodes halves. Company Services Swiss SA Group solution is user friendly and offers outstanding mechanical properties.

ANODE GAP INFILL AFTER APPLICATION

A specially designed Solid PU for manual mix & pour will be poured onto the anode gap-filling it entirely and rapidly, offering a sturdy, durable, and consistent solution with mechanical properties over those of CWC.

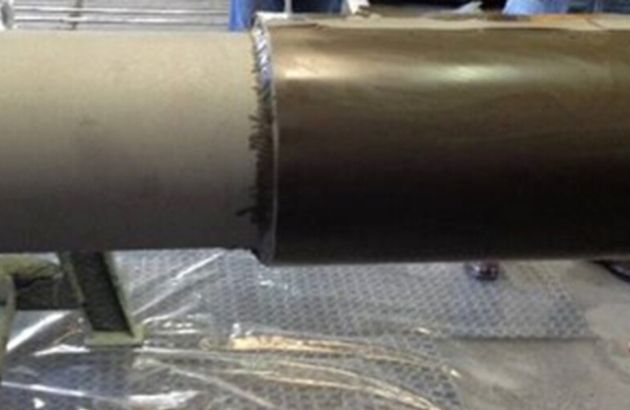

RISER PIPES COATING

RISER PIPES COATING

The coating of riser pipes requires a robust, durable, and easy to apply and repair solution. A specially designed Solid PU for manual mix & pour will be utilized to offer a coating of typically 20 mm thickness on the pipe.

SPACER RINGS

SACRIFICIAL SPACER RINGS

Among the range of Polyurethanes manufactured from CSS SA Group, one solution is specially developed to build up sacrificial spacer easily rings moulded onto a 3LPE or 3LPP pipe to protect it from abrasion and wear.

One application which is ongoing for many years is the protection of the parent coating of O&G pipelines in the concrete micro tunnels sections, thus ensuring easy pulling of the pipes in the micro tunnel without damaging the parent coating.

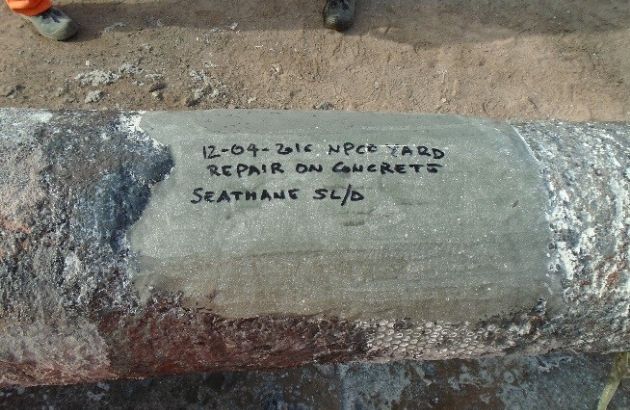

CWC COATING REPAIR & CWC COATING REPAIR MATERIALS

CWC COATING REPAIR BEFORE APPLICATION

CSS SA Group has developed a user-friendly solution for the repairs of CWC, a specially designed Solid Polyurethane for manual mix & pour, which is directly applied onto the area to be repaired and quickly hardening to restore the profile of the CWC and the mechanical strength.

CWC COATING REPAIR AFTER APPLICATION

CSS SA Group manually mixes and applies solutions for CWC repairs offer outstanding adhesion on the CWC and mechanical properties exceeding those of CWC.

Company Services Swiss SA Group’s Technical and Commercial responsiveness is happy to receive your enquiry and reply in the shortest lead time.